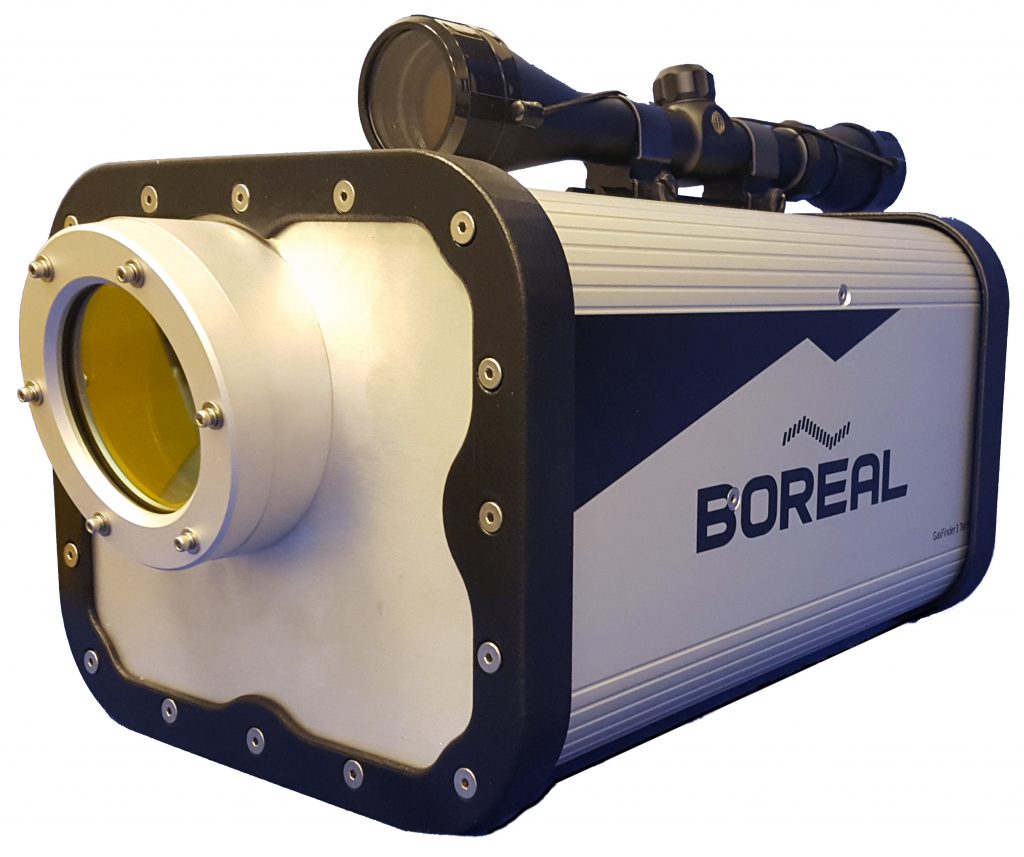

GasFinder Enclosure

The new digital gas analyzer platform for Boreal Laser needed a new, more modern look, so I designed and worked with an aluminum extrusion manufacturer to get a custom die made and aluminum drawn. Through design discussions with the manufacturer I learned many of the realities and considerations of working with extruded material. There was significant benefit to going this route, as having a custom extrusion allowed for slightly different product applications and cut lengths. I also designed and prepared the endcaps for sandcasting. The endcaps sealed with custom gaskets. In the end the extrusion was used primarily for a new mid-infrared gas detector. It met IP66 enclosure sealing requirements and could withstand temperatures from -40 to +50 C.

Software used: Solidworks. Renders done using Photoview 360 Solidworks add-in. 3D printed prototype validation carried out using Slic3r and Repetier software on a Machinacorp Mk2 printer. Photos edited using Photoshop.

Work done in 2015.